Biodiesel

What is biodiesel?

Plant and animal fats and oils are acids of long hydrocarbon chains similar to their fossil-fuel counterparts.Some can be directly usable as fuels, but most are too viscous to be used directly and are converted to their methyl esters (Fatty acid methyl ester :FAMEs) to be used as fuels. Fat or oil "transesterified" by combination with methanol—substitutes directly for diesel. This fuel known as biodiesel burns cleaner as it contains oxygen. Glycerin, a by-product of esterification can also be used in variety of ways. (Ref : NREL article 2002)

Advantage of Biodiesel as a fuel alternative – it can be seamlessly integrated into existing transport infrastructure. Without modification diesel engine can run on any mix from 10% (B10) to 100% (B100), present tanks and pumping system require little alteration. It reduces exhaust pollution and engine maintenance cost. European Union leads biodiesel technology and has plans to import the biomass required from developing countries.

Top producer in EU are Germany, France, Italy & Spain & other leaders were USA, Brazil & Thailand etc.

Plant Resources for Biodiesel

Biodiesel, in principle can be produced from any vegetable oil. In US it was it is mostly derived from Soybean while in Europe biodiesel was obtained from mustard seeds. (Ref: Review by TIFAC, 2010). In Asian countries like Malaysia Palm oil is used for biodiesel. In India non edible seeds, particularly Jatropha and Pongamia are extracted for its oil. (See below).

Soybean Glycine max

(Image source – Wikipedia)

Rapeseed (Brassica napus)

(Image source – Wikipedia)

Oil palm (Elaeis guineensis)

(Image source – Wikipedia)

Constraints/ Challenges for biodiesel technology (Plant biomass)

- Intensive plantations especially on wastelands may mean extensive use of pesticides, fertilizers, machinery thus making it harder for environmental, economic sustainability.

- Inadequate supply of biomass (Argument over scientific basis for a viable yield of biodiesel from plants).

- Land use pattern change: Degraded forests, wastelands if exclusively used for biodiesel plantation may deprive rural communities dependent on them and companies may control the lands in a centralized manner not suitable for local habitats. On the other hand if agricultural land is used for cultivating non-edible biofuel crops, it would create food vs. fuel situation ( Ref: Nagar 2008).

Biodiesel from Algae

Third generation of biofuels – algae and related aquatic organisms can be an ideal resource for sustainable, low carbon economy. They offer multiple advantages due to their efficient photosynthetic capacity (can mitigate CO2 emissions better), higher oil yield and other versatile byproducts (likely to contribute to economic viability). Due to their diverse habitats and survival on waste water, these organisms do not compete for water or land use with agricultural crops. On the other hand, wastewater treatment can be an added advantage of the technology. Exhausts from power plants or cement industries contain large amounts of CO2. An algal biofuel plant adjacent to these may provide an efficient way to utilize this CO2.

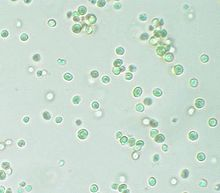

Nanochlropsis – microalgae with high lipid

(Image source – Wikipedia)

Scope for Research and Technology for Algal Biofuels

Higher oil yields can be possibly obtained from microalgae grown in photobioreactors with controlled conditions. However such reactors are capital – intensive for cost and operations compared to open ponds. Therefore significant research is required to determine influence of various factors in an open pond to establish assured productivity( Ref : Review by TIFAC, 2010). Technologies to develop low-cost bioreactors offering full/ part control of parameters will also be useful. Technologies for low cost drying options, using wet algal biomass for transesterifcation would help in cutting the cost. ( Ref : Gude et al. 2012)

Biodiesel in India

Jatropha curcas Pongamia pinata

(Image source – Wikipedia) (Image source – Wikipedia)

Biodiesel would be the ideal solution for India's biofuel program. India heavily depends on import of oil and non edible oil from Jatropha can, in theory provide an answer to supply issue.

Other advantages –

- Jatropha is hardy, perennial shrub capable of growing in dry, infertile lands. Planting Jatropha has thus an additional advantage of phytoremediation. Jatropha oil yield 1 to 5 tonnes/ ha depending upon the soil conditions and rain fall. Seeds from plantation will start coming after 3 -4 years.

- Biodiesel projects from Jatropha oil can also create new employment opportunities in agricultural and small and medium industrial sectors.

- Mitigation of greenhouse gas emission through CO2 sequestration to the extent of approximately 10 tonnes CO2 per hectare can be realized by Jatropha plantations. Since India is a developing country, this can be traded under the Clean Development Mechanism (CDM).

- Can also be a source for biomass

Examples of initiatives taken in India: a. Daimler – Chrysler- CSIR initiative - 5000 km trial run of a Mercedes Benz sedan was completed, powered by Jatropha biodiesel.

Image source: Daimler presentation UNEP conference

b. D1 oils (UK) doing large scale Jatropha plantations with Mohan Breweries. c. Indian oils – Indian Railways collaboration for supply of biodiesel. Some railways engines in use for 5% biodiesel blend (Southern railways) (Ref : Frost and Sullivan Report 2005 ). Plants being set at Raipur and Chennai to esterify waste cooking oils, non edible oils Pongamia plantations are also encouraged and initiated as border, forest plantations etc.

c. RSDO (Railways' Research Design and Standard Organization ) developed and tested biodiesel-based locomotive engines. d. Researchers from CSMCRI and Ministry of Earth Sciences used diesel from marine microalgae to fuel Chevrolet Tavera on 20% biodiesel (Ref : Biodiesel technologiesIndia).

A total of 3,470 metric tons (1.04 million gallons) per day of biodiesel production has been established within the country by private industry (Ref: Press Information Bureau, Govt of India). Main resource plants for biodiesel are Jatropha or Pongamia. More than 9 lakh hectares are under cultivation for Jatropha. However lack of superior quality germ-plasm, agricultural practices results into suboptimal yield of seeds which are not stored adequately. The long-term production potential of biodiesel is constrained by the limited availability of cultivable wasteland that could be brought under biodiesel plantations. Slim margin for financial gains discourages farmers from taking initiative. There is disagreement between oil marketing companies and biodiesel manufacturers about the price or purchase.

India various public sector (Indian Oil) as well private sector (Reliance Technology) endeavors are ongoing for this third generation biofuel technology. This also includes start ups like Sea 6 (Ref: Table of biofuel companies in India)

Biodiesel Technology in Pune: Various academic institutes in Pune are involved in developing biomass for biodiesel. Some examples include : tropical oleaginous fungi from mangroves at IBB (Ref : Khot et al. 2012), oleaginous yeasts at Bharati Vidyapeeth (Ref : Jadhav et al. 2012), freshwater algae at Department of Botany, University of Pune (Ref : Mahale and Chaugule 2013). Technology optimization efforts are also ongoing viz. bioreactor from recycled water bottle (Ref : Topare et al. 2012), biodiesel production from Jatropha (Topare et al. 2011), performance testing of biodiesel in a C. I. engine (Nagarhalli et al. 2010).

Challenges to biodiesel technology in India - Compared to "ethanol" technology biodiesel is comparatively new and farmers are not familiar with the crops.(Ref : Shahnila Islam 2012) and the sector lags due to discursive efforts by state and industry (Ref : Nagar 2008). Blending of biodiesel is not a law yet. There is no minimum support price for biodiesel. India excessively depends on Jatropha and Pongamia. Germplasm for these crops is limited and is distributed unevenly. (Ref : MNRE report on biofuels).

Scope for Technologies

- Developing biodiesel from various non edible oils and testing its performance in vehicle engines. Technologies to use low cost, high oil feedstocks would cut down upon cost of biodiesel.

- Technologies to produce/identify quality planting material. (Ref : Pisces report on India's bioenergy 2011)

- Technologies for formulation, implementation and validation of standards for biodiesel production and sale.

- Developing effective mechanisms for seed collection and low cost technologies for oil extraction especially for rural areas.

- Self help groups/NGOs linkage with companies for organized programs on plantation, operation of de-centralized plants and distribution. Design, development and fabricate low cost, pilot scale bio-reactors for cultivation of algae (Ref : MNRE report on biofuels)

- Technologies for better extraction of seed oils. Use of energy efficient, non-conventional technologies such as ultrasonics and microwaves (Ref : Gude et al. 2012)

- Detoxification of Jatropha oil cake to be used as animal feed (Ref : Review by TIFAC, 2010)

- Developing, testing and commercializing engines of various capacities running on biodiesel for stationary applications.

- Developing generators that run on biodiesel for rural electrification.

- Technologies for algal biodiesel (as listed in the related section above)